Flite-Veyor® Flat Bottom Chain Conveyors

Flat Bottom Chain Conveyors designed for durability and long-lasting performance

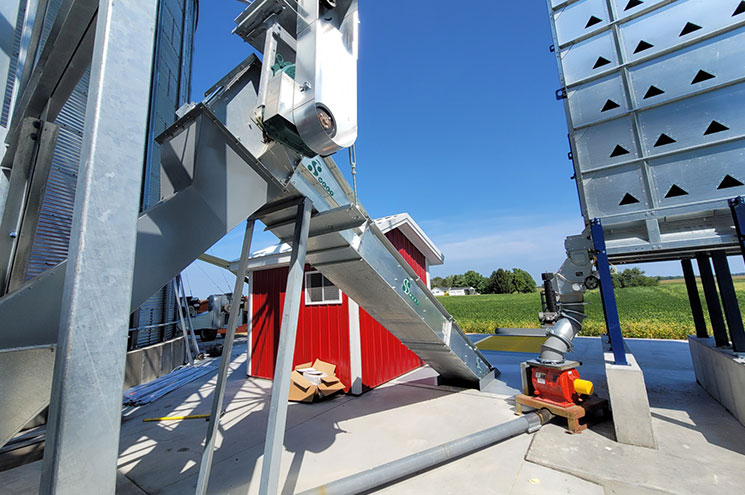

Sweet Manufacturing’s Flat Bottom Flite-Veyor® Conveyors are the perfect solution for efficient material handling in a wide range of industries. Designed with precision and built to withstand the toughest conditions, our flat bottom conveyors deliver reliable performance, durability, and optimal productivity.

Overview

Flite-Veyor®

Flat Bottom Chain Conveyors

Flite-Veyor®

Round Bottom Chain Conveyors

High Performance Equipment With Quiet Operation

With its fully-enclosed design, the Flite-Veyor® Flat Bottom Chain Conveyor offers quiet operation to gently yet quickly convey bulk materials horizontally, on an incline, and in low-profile configurations. Our heavy-duty chain features UHMW polyethylene flights for positive flow and reduced friction. Models are available in a 12, 17, 26, and 33-inch height product series, with capacities of 1,000 – 50,000 BPH (25 – 1,355 MTPH).

Sweet Manufacturing’s Flat Bottom Flite-Veyor® Conveyors find applications in various industries, including agriculture, food processing, feed manufacturing, seed handling, and more.

Versatile and Reliable Design

Our Flat Bottom Flite-Veyor® Conveyors feature a versatile and reliable design that allows for seamless movement of various materials, including grains, seeds, feed, fertilizer, and more. With a flat bottom and gentle handling, these conveyors ensure minimal product damage while maintaining a consistent flow.

Our Process

Providing Material Handling Solutions Designed For You

Inquiry

Submit an online request or call, and our Sales Representatives will connect you with an Authorized Sweet Dealer in your area. During the inquiry phase, we will provide estimated lead times.

Quoting

We work closely with our dealers to gather more information regarding the request & tailor a solution to meet your needs. During the quoting phase, we will provide an itemized quote, payment terms, and approval drawings upon request.

Order

Your order will be processed once we receive your purchase order or signed estimate. After this process, if you require assistance to set up your equipment, our Authorized Sweet Dealer will work with you to coordinate installation.

Jordan Gunter

Gunter Peanut Company | Binger, OK