ENHANCING EFFICIENCY AND QUALITY IN MECHANICAL OIL EXTRACTION

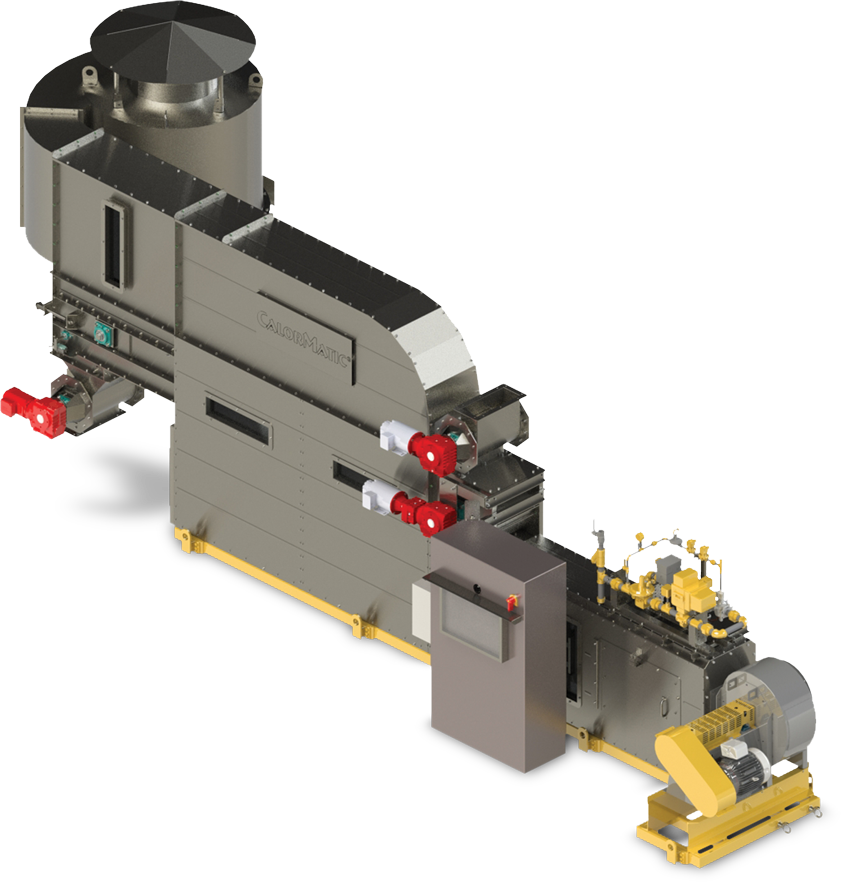

Preheating oilseeds before mechanical extraction is essential for maximizing oil yield and quality. The CalorMatic® fluidized bed dryer excels in preparing oilseeds like soybeans for this process. Using a high-temperature, short-time approach, the CalorMatic® reduces moisture content, enhancing the efficiency of the crushing stage. It reduces oil viscosity, improves flow and yield, and breaks down seed cell walls to enhance oil release, especially in hard-shelled seeds. This process preserves nutritional value by maintaining protein levels and solubility.

Preheating soybeans increases protein and preserves solubility, benefiting animal feed. It also reduces antinutritional factors, improving meal quality. Traditional methods will reduce protein solubility due to high heat during prolonged periods. The CalorMatic®‘s advanced automation ensures optimal drying conditions, making it indispensable for modern oilseed processing. Prioritizing preheating with a CalorMatic® achieves superior results.

Preheating maintains oilseeds’ nutritional value and quality: Preheating the oilseeds (soybeans) to 250° F–275° F will gently reduce the moisture content from 15%–19% to 8%–9%, increasing protein content by weight. This moisture reduction ensures that solubility levels are preserved for the best animal benefit (75%–95%). Oil content is also increased by dry weight due to reduced moisture content.

Preheating oilseeds (soybeans) will also reduce the antinutritional factors below 5,000 TIU/gr. The CalorMatic®‘s automation allows operators to adjust these reduction levels to lower or higher values. Traditional drying methods can reduce the moisture content. Still, they can affect nutritional values because they require longer exposure to reduce moisture content and could affect protein solubility, leading to protein quality degradation. However, the CalorMatic® addresses these challenges through its advanced automation and control systems, ensuring optimal drying conditions (high temperature in a short period) for oilseeds protein meal production.

Preheating improves oilseed extraction efficiency: It reduces viscosity and enhances oil flow. This results in higher yields and faster processes. Preheating oilseeds lowers the oil’s density, improving extraction. For example, heated seeds break down cell walls, releasing more oil. This is crucial for oilseeds with tough shells or high oil content, like soybeans. The result is a significant increase in oil yield. Increased efficiency and throughput are vital in large-scale operations. Thus, heating boosts productivity and profitability. Enhanced extraction methods lead to better economic outcomes. Efficient extraction processes benefit the entire supply chain. This highlights the importance of preheating in oilseed processing.

Enhancing oil quality through preheating: Preheating seeds enhances oil quality by reducing impurities and moisture, ensuring a higher-grade product vital for market competitiveness. Heating eliminates moisture, minimizing microbial growth and spoilage, as is exemplified by preheated sunflower seeds producing oil with fewer impurities. This process enhances the oil’s shelf life and stability, crucial for storage and transportation. High-quality oil meets industry standards and consumer expectations by adopting preheating practices, essential for maintaining product integrity. Improved oil quality directly impacts marketability and profitability, making preheating vital for producing high-quality, market-ready oil, enhancing yield, and ensuring superior quality.

Conclusion

The CalorMatic® fluidized bed dryer is essential for preheating oilseeds, optimizing yield, and preserving nutritional quality. It efficiently reduces moisture, increases protein content, and maintains solubility, benefiting animal feed. The advanced automation of the CalorMatic® ensures consistent and high-quality oilseed processing, making it indispensable for modern operations. Reducing viscosity and breaking down cell walls enhances oil extraction and yield, which is crucial for large-scale production. Preheating also improves oil quality by minimizing impurities and moisture. For reliable and superior oilseed processing, the CalorMatic® is your best choice. Prioritize CalorMatic® for top-tier results in plant protein diets and oil production.

Takeaway Option 1: Investing in the CalorMatic® for preheating oilseeds ensures optimal efficiency and quality in mechanical oil extraction, leading to higher profitability, improved resource utilization, and market-ready oil of exceptional quality.

Takeaway Option 2: Investing in the CalorMatic® ensures optimal oilseed processing, maximizing yield, quality, and nutritional value for superior plant protein diets and oil production.