Flite-Veyor® QL 17 Series Flat Bottom Drag Conveyor

Maximize Efficiency with QL 17 Series Flat Bottom Drag Conveyors

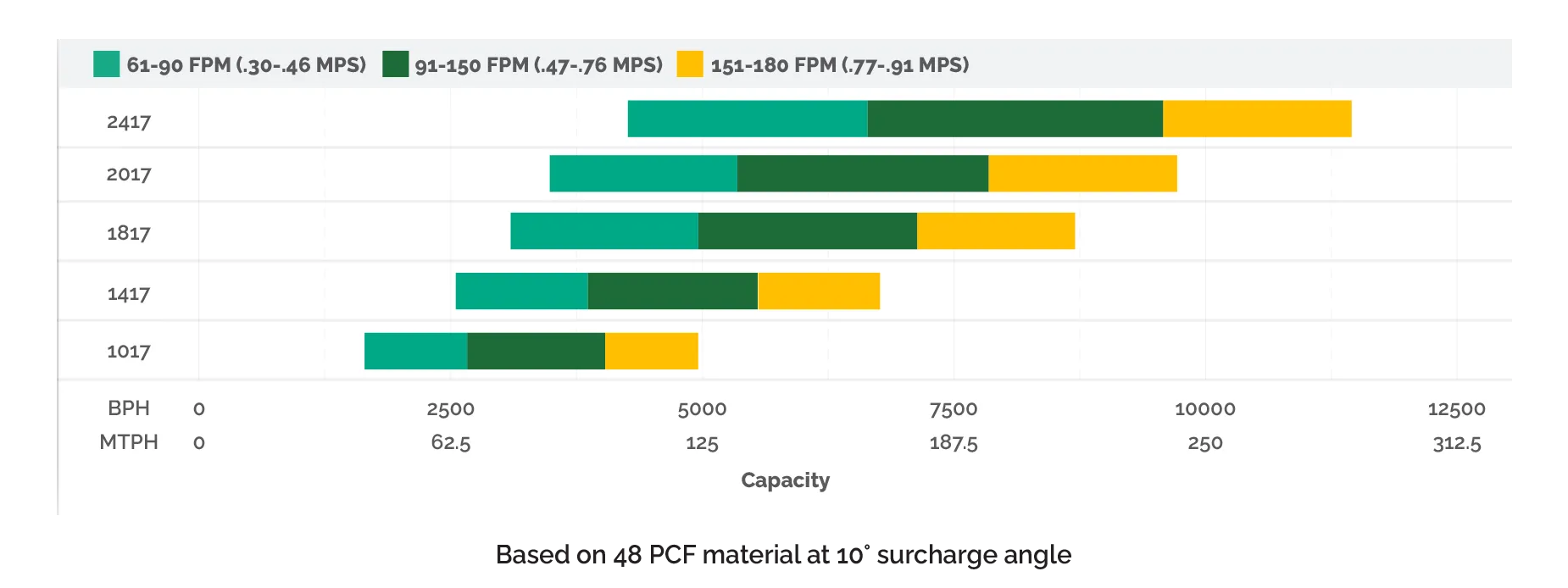

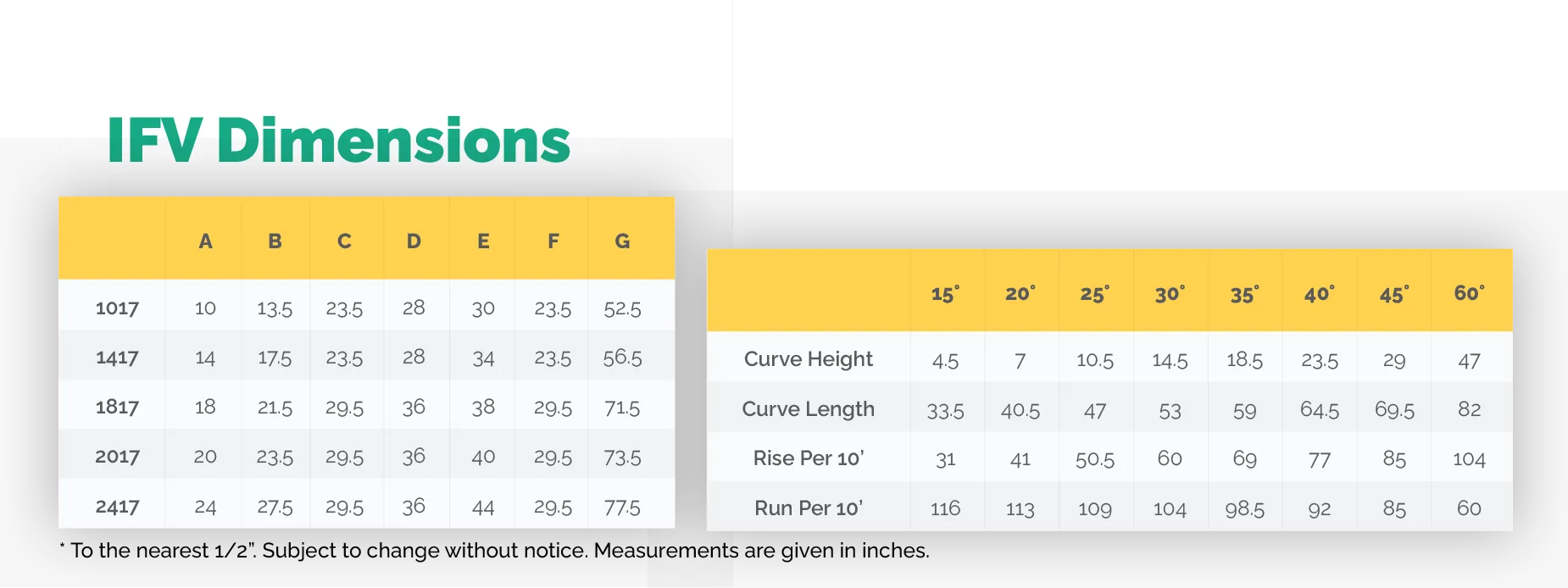

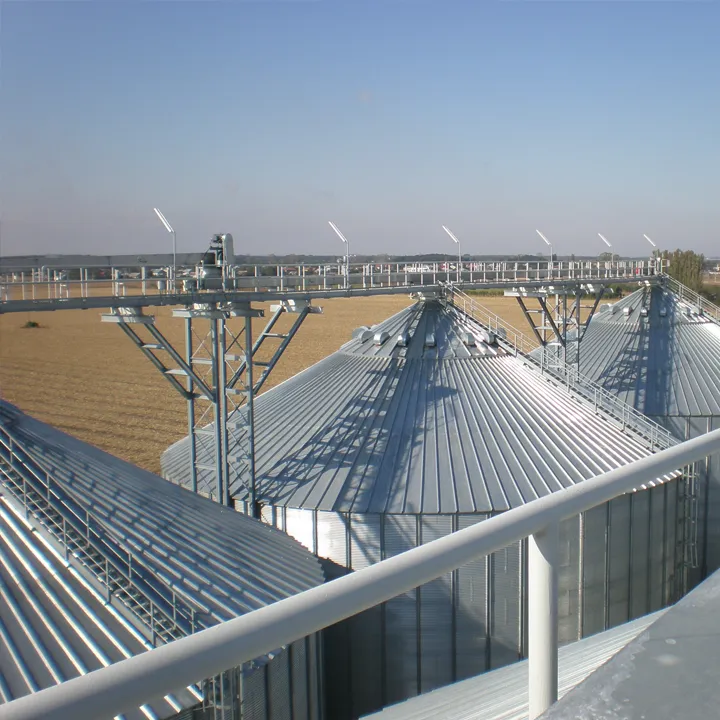

With both Horizontal Flat Bottom and Incline Flat Bottom options available, our drag conveyors provide reliable performance, exceptional durability, and seamless operation in various applications.

Overview

Round Bottom Chain Conveyors

Flat Bottom Drag Conveyor

Heavy-Duty Design Inspired by Performance

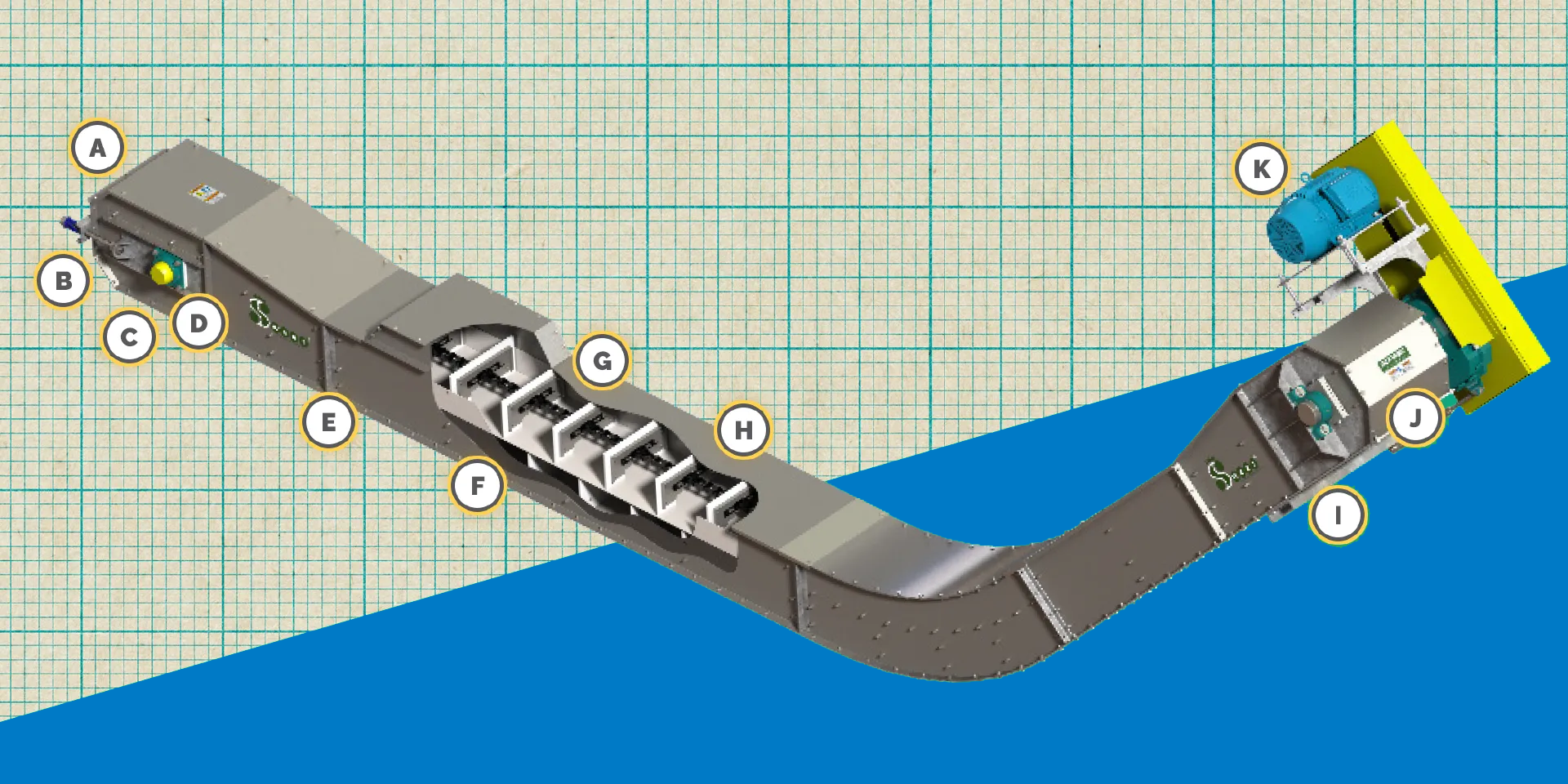

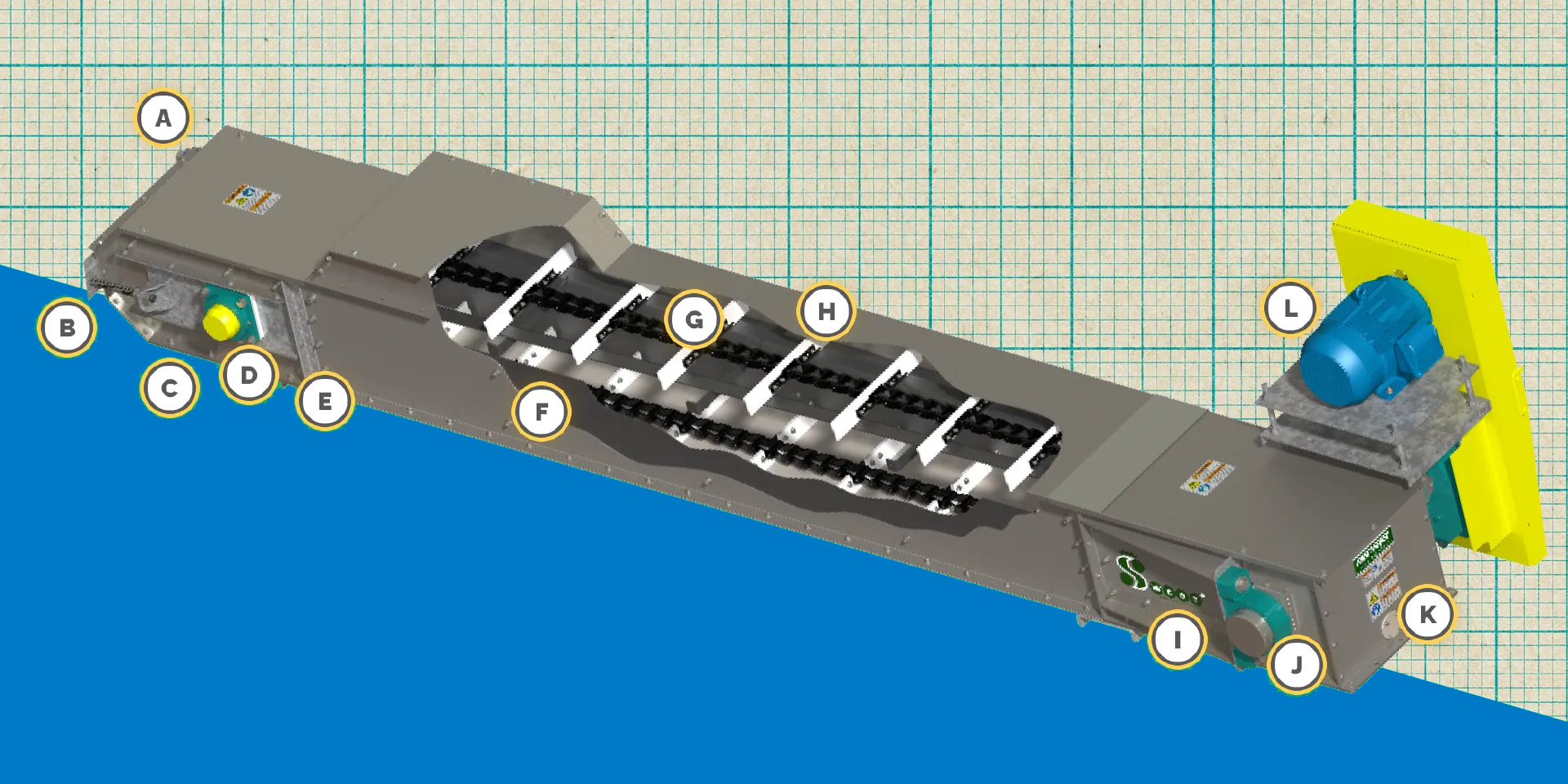

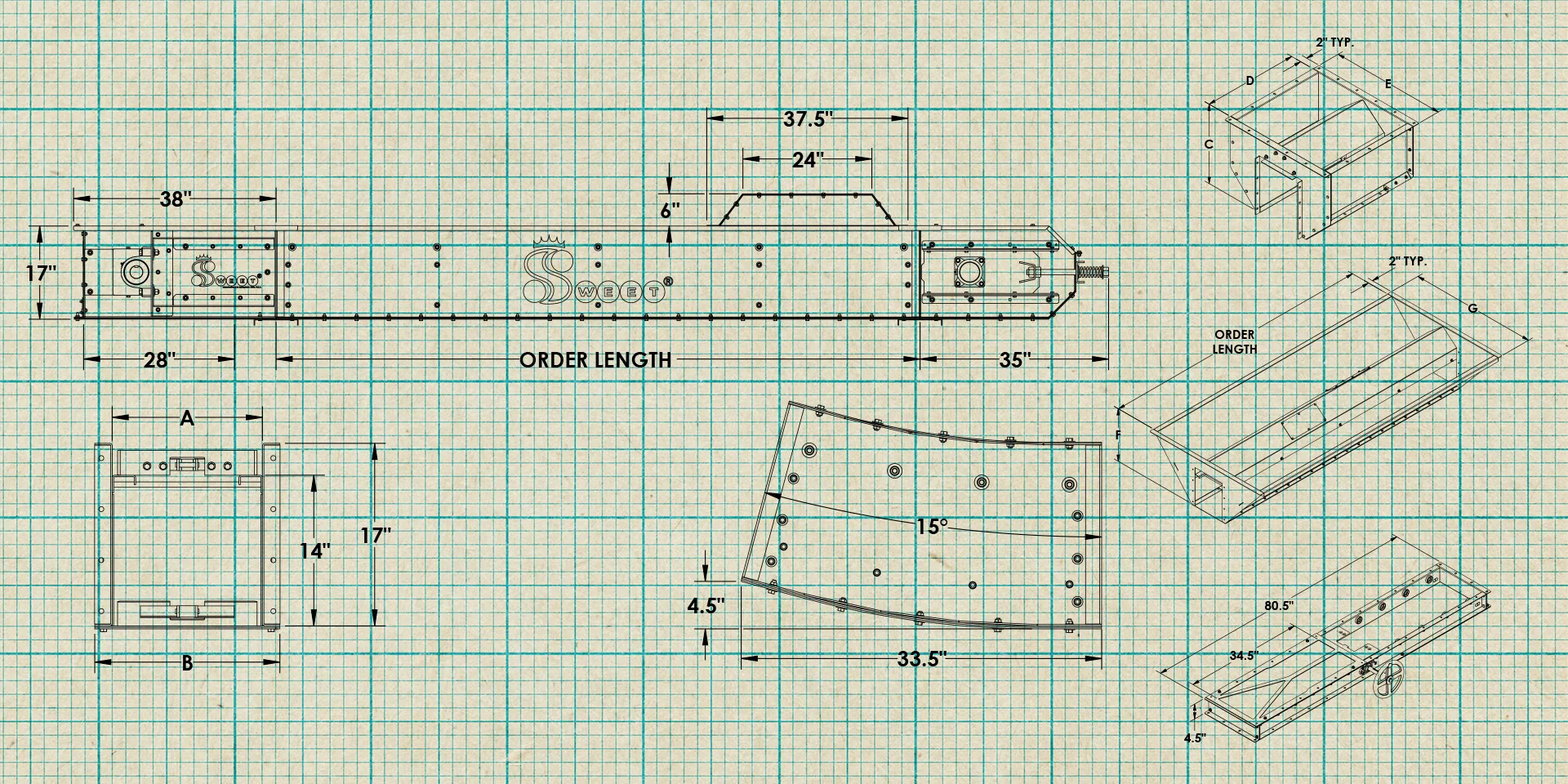

Key Features on the Flite-Veyor® QL 17 Series Incline Flat Bottom Drag Conveyor (IFV)

Tail

Heavy-duty take-up plate weldments

Trough

10-gauge 3/16” and 1/4” AR 200 liner and 3/16” and 1/4” AR 400 liner available

10-gauge galvanized sides and bottom standard

Head

Key Features on the Flite-Veyor® QL 17 Series Horizontal Flat Bottom Drag Conveyor (HFV)

Tail

Heavy-duty take-up plate weldments

Trough

10-gauge 3/16” and 1/4” AR 200 liner and 3/16” and 1/4” AR 400 liner available

10-gauge galvanized sides and bottom standard

Angle rail returns

Head

IFV & HFV Options

Sweet Manufacturing’s entire team of engineers, technicians and customer service representatives work with you to build the ideal chain conveyor system that fits your company’s unique requirements from these conveyor types:

Extra Standard Inlet

Standard inlets are recommended for use in applications where material flow is controlled before entering the conveyor.

Bypass Inlet

Bypass inlets funnel material directly into the lower portion of the trough. This feeding method provides automatic flow control into the conveyor, preventing pressure buildup on the chain. Bypass inlets are recommended when flow control is not provided before entering the conveyor.

Dump Hopper

Dump hoppers replace a section of the trough for use in pit applications. The hopper diverts material around the return chain and provides an even flow into the lower portion of the Flite-Veyor®. This prevents pressure buildup on the chain and reduces horsepower requirements. Dump hoppers are available in standard 10′.

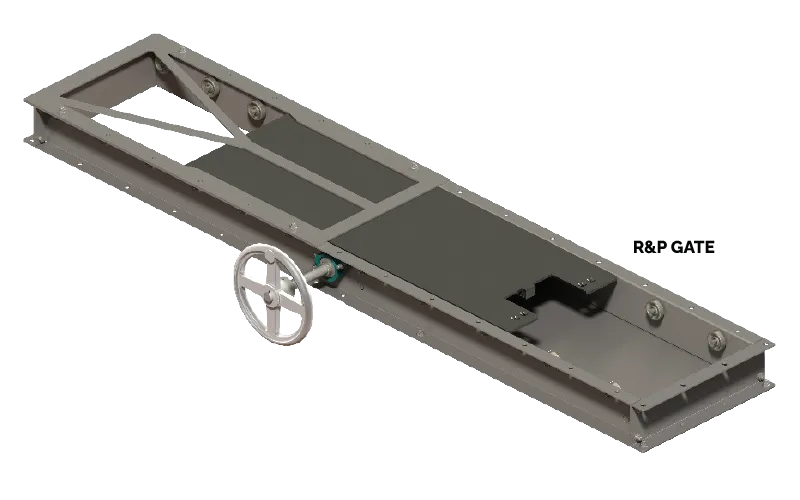

Intermediate Discharge

Intermediate discharges have a steel cutout plate to support the chain over the opening while allowing 100% of the material to discharge. Intermediate discharges are available with manual, electric, or pneumatic controls.

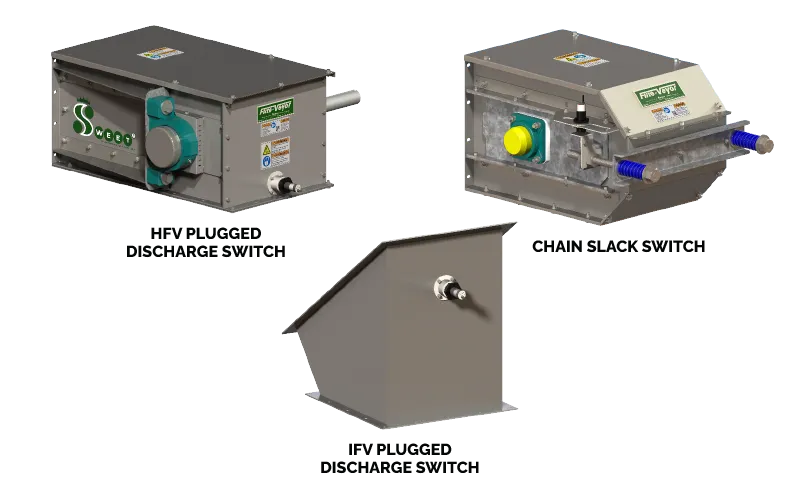

Sensor Kits

Sensor Kits are available to automate monitoring of conveyor operations.

QL 17 Series Flat Bottom Drag Conveyors are designed for durability and long-lasting performance

Our Flat Bottom Flite-Veyor® Conveyors feature a versatile and reliable design that allows for seamless movement of various materials, including grains, seeds, feed, fertilizer, and more. With a flat bottom and gentle handling, these conveyors ensure minimal product damage while maintaining a consistent flow.

Learn more about our Enclosed Belt Conveyors by downloading our brochure, technical manual and additional information

Brochure

Brochure

Flite-Veyor® QL 17 Series Conveyor

Our Process

Providing Material Handling Solutions Designed For You

Inquiry

Submit an online request or call, and our Sales Representatives will connect you with an Authorized Sweet Dealer in your area. During the inquiry phase, we will provide estimated lead times.

Quoting

We work closely with our dealers to gather more information regarding the request & tailor a solution to meet your needs. During the quoting phase, we will provide an itemized quote, payment terms, and approval drawings upon request.

Order

Your order will be processed once we receive your purchase order or signed estimate. After this process, if you require assistance to set up your equipment, our Authorized Sweet Dealer will work with you to coordinate installation.

Jose Enrique Hernandez

SESEYA & UCAY Cooperative | Mexico